Proven Methods on How to Fix Vibrating Water Pipes

Are you dealing with the annoying problem of vibrating water pipes? Don’t worry, we’ve got you covered. In this article, we will explore proven methods to fix vibrating water pipes and provide practical tips to solve this plumbing issue once and for all. Whether you’re a homeowner or a professional plumber, these solutions will help you put an end to pipe vibrations and enjoy a quieter plumbing system.

Key Takeaways:

- Water hammer, also known as hydrostatic shock, can cause vibrations in water pipes.

- Identifying the causes of water hammer is crucial for effective solutions.

- Piping vibration can lead to serious risks and requires regular integrity assessment.

- Proper pipe design, support, and regular maintenance are essential for preventing water hammer.

- Reducing excitation, increasing pipe diameter, and using surge tanks are effective solutions to fix vibrating water pipes.

Understanding Water Hammer and its Causes

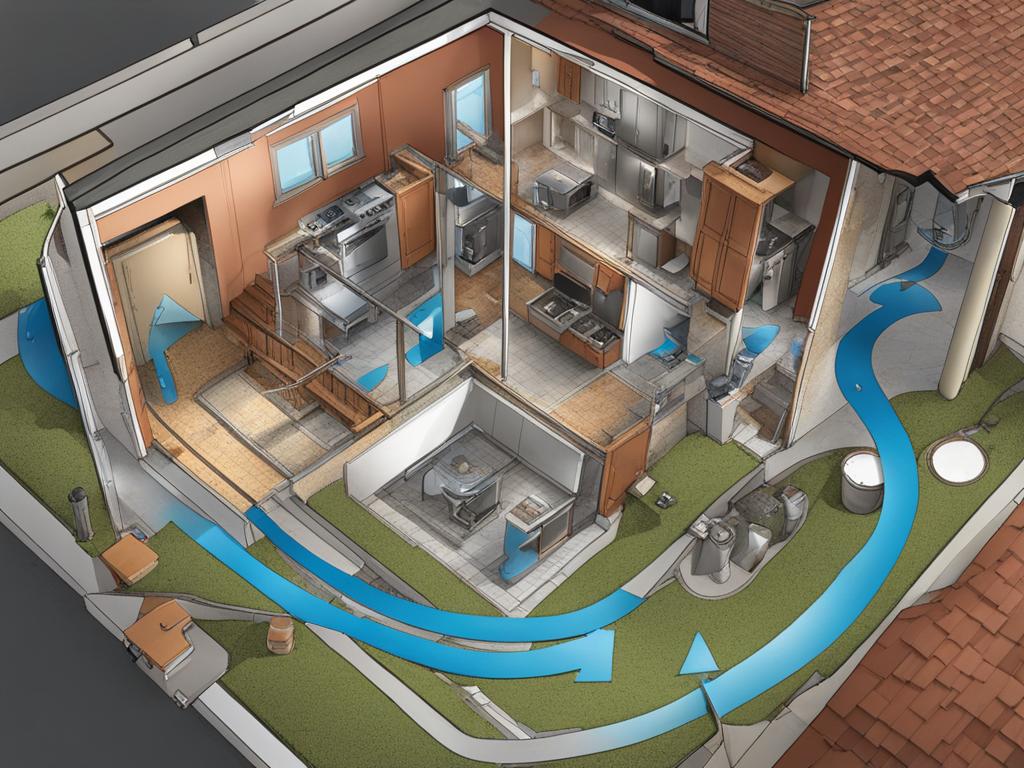

Water hammer, also known as hydrostatic shock, is a common plumbing issue that can cause vibrations in water pipes. It occurs when there is a sudden change in fluid velocity, resulting in a large pressure fluctuation and the release of energy. This abrupt change can be triggered by factors such as valves shutting off quickly or pumps starting or stopping suddenly. The primary sources of water hammer include acoustic/pulsation, momentum, and machinery. Identifying the causes of water hammer is crucial in effectively addressing the issue and preventing further damage.

Water hammer can have severe consequences, including burst pipes, damaged supports, leakage at joints, and even structure collapse. The shock wave caused by water hammer travels along the pipe, changing fluid velocity and creating high-pressure zones. If the wave encounters pipe bends, it can cause out-of-balance forces, leading to pipe movement and potential failure. Therefore, it is essential to address water hammer promptly to prevent further damage and ensure the integrity of the piping system.

To accurately diagnose water hammer, one must observe pipe movements, listen for banging noises, and monitor flowrate changes. Diagnosing water hammer in plumbing systems involves identifying the sources of noise and vibrations. Common signs of water hammer include banging water pipes, clanging, rattling, or rumbling noises when a plumbing fixture or valve shuts off. By accurately diagnosing water hammer, appropriate solutions can be determined and implemented to prevent further damage and restore the tranquility of the plumbing system.

Common Causes of Water Hammer

- Valves closing too quickly

- Pumps starting or stopping suddenly

- Water flowrate changes

- Misaligned piping systems

- Piping system design flaws

Risks of Piping Vibration and Integrity Assessment

Piping systems are highly susceptible to vibration-induced failures, which can pose significant risks to the overall integrity of facilities, equipment, and personnel safety. These failures can result in catastrophic consequences such as explosions, environmental damage, and facility shutdowns. Therefore, it is crucial to conduct a thorough piping vibration analysis and integrity assessment to proactively identify and mitigate potential risks.

Piping Vibration Risks:

- Structural damage to pipes, supports, and surrounding equipment

- Leakage or failure at joints and connections

- Increased stress and fatigue on piping components

- Disruption of fluid flow and system performance

Integrity Assessment:

An integral part of managing piping vibration risks is the implementation of an integrity assessment program. This program involves evaluating the current condition of the piping system, identifying potential vulnerabilities, and determining appropriate remedial actions. The Energy Institute AVIFF Guideline provides a recommended approach for conducting integrity assessments, which includes:

- Reviewing historical data and past incidents

- Inspecting pipe supports, hangers, and anchors

- Performing mechanical integrity testing

- Conducting fluid dynamics analysis to identify potential vibration sources

- Implementing risk-based inspections and monitoring

By conducting regular integrity assessments and adopting a risk-based approach, facilities can effectively manage and mitigate piping vibration risks. This proactive approach helps prevent unforeseen failures, enhances safety, and ensures the prolonged integrity and reliable operation of the piping system.

| Integrity Assessment Steps | Description |

|---|---|

| Review historical data and past incidents | Examine previous incidents, failures, or maintenance logs to identify recurring or potential issues. |

| Inspect pipe supports, hangers, and anchors | Check the condition and stability of pipe supports, ensuring they are adequately designed to withstand vibration and other forces. |

| Perform mechanical integrity testing | Conduct non-destructive testing (NDT) and evaluations to identify defects and potential weaknesses in the piping system. |

| Conduct fluid dynamics analysis | Utilize computational fluid dynamics (CFD) or other analytical methods to model fluid flow and identify potential vibration sources. |

| Implement risk-based inspections and monitoring | Establish a systematic approach for monitoring and inspecting high-risk areas and critical piping components based on their importance and potential consequences of failure. |

By following these best practices and integrating integrity assessments into maintenance and management programs, facilities can effectively mitigate piping vibration risks, enhance system reliability, and ensure the safe and uninterrupted operation of their piping systems.

Identifying Water Hammer Situations

Identifying potential water hammer situations is crucial for preventing damage and ensuring the smooth operation of plumbing systems. While there are no simple rules to spot water hammer potential, various methods can be used to identify and address this issue effectively.

One approach is to utilize computer programs that can model pipe systems and reveal potential water hammer problems. These software programs allow for the analysis of pipe systems, helping to identify potential issues and test potential solutions. Using suitable software can accurately identify and resolve water hammer issues, especially when dealing with pipes carrying toxic or flammable materials.

In addition to computer simulations, visual observations and monitoring can also play a role in identifying water hammer situations. Paying attention to signs such as sudden movements or noises in the plumbing system can provide valuable insights into the presence of water hammer. By being proactive and vigilant, potential water hammer situations can be identified and addressed before they cause further damage.

| Signs of Water Hammer | Potential Causes |

|---|---|

| Banging water pipes, clanging, rattling, or rumbling noises | Valves shutting off quickly, pumps starting or stopping suddenly |

| Sudden pipe movements | Changes in fluid velocity, flowrate, or direction |

| Visible damage or leaks at joints | Water hammer-induced stress on pipe connections |

Effects of Water Hammer and Consequences

Water hammer can have severe consequences, including burst pipes, damaged supports, leakage at joints, and even structure collapse. The shock wave caused by water hammer travels along the pipe, changing fluid velocity and creating high-pressure zones. If the wave encounters pipe bends, it can cause out-of-balance forces, leading to pipe movement and potential failure. It is essential to address water hammer promptly to prevent further damage and ensure the integrity of the piping system.

One of the primary effects of water hammer is pipe damage. The intense pressure fluctuations and vibrations can weaken the pipe material over time, increasing the risk of leaks, cracks, and pipe failures. These failures not only result in costly repairs but can also lead to water wastage, property damage, and potential safety hazards.

Additionally, water hammer can cause damage to pipe supports and fittings. The sudden pressure surges can exert significant forces on the supports, causing them to bend, break, or detach from the structure. This can compromise the stability and functionality of the entire piping system, leading to operational disruptions and potential accidents.

| Consequences of Water Hammer |

|---|

| Pipe damage: Burst pipes, leaks, cracks, and failures |

| Support and fitting damage: Bent, broken, or detached supports |

| Operational disruptions: Water supply interruptions, system downtime |

| Safety hazards: Potential accidents, structural collapse |

“Water hammer is a quiet thief in the plumbing system. It may start as subtle vibrations and noises, but over time, it can cause significant damage if left unaddressed. By understanding the effects of water hammer and taking immediate corrective measures, facilities can protect their infrastructure and maintain a reliable plumbing system.” – Plumbing expert

How to Diagnose Water Hammer in Plumbing Systems

To effectively address water hammer issues in plumbing systems, accurate diagnosis is crucial. Diagnosing water hammer involves identifying the sources of noise and vibrations that occur during the operation of plumbing fixtures or valves. By observing pipe movements, listening for specific noises such as banging or clanging, and monitoring flowrate changes, one can determine the presence of water hammer.

Diagnosing water hammer is a critical step in finding appropriate solutions and preventing further damage to the piping system. It enables plumbing professionals to pinpoint the specific locations and causes of water hammer occurrences, allowing for targeted interventions. By accurately diagnosing water hammer, one can effectively mitigate the risks associated with this phenomenon and ensure the smooth operation of the plumbing system.

In some cases, it may be necessary to use advanced tools and techniques for diagnosing water hammer, such as pressure sensors or vibration analysis equipment. These tools provide more precise data and insights into the behavior of the plumbing system. By leveraging modern diagnostic technologies, plumbing professionals can make informed decisions and implement effective solutions to fix vibrating water pipes caused by water hammer.

Common Signs of Water Hammer:

- Banging water pipes

- Clanging, rattling, or rumbling noises when fixtures or valves shut off

- Visible pipe movements

- Flowrate fluctuation

Steps to Diagnose Water Hammer:

- Observe pipe movements and check for visible damage or abnormalities.

- Listen for specific noises associated with water hammer, such as banging or clanging.

- Monitor flowrate changes during the operation of plumbing fixtures or valves.

- Consider using advanced diagnostic tools, such as pressure sensors or vibration analysis equipment, for more precise data.

By following these steps and utilizing appropriate diagnostic tools, plumbing professionals can accurately diagnose water hammer in plumbing systems. This knowledge is essential for implementing the right solutions and preventing further damage, ensuring a quieter and more reliable plumbing system.

Solutions to Fix Vibrating Water Pipes

The issue of vibrating water pipes caused by water hammer can be effectively addressed using various proven solutions. By implementing these remedies, you can reduce the level of excitation and mitigate the risks associated with water hammer.

Slowing Down Valve Closures and Pump Operations

One solution to fix vibrating water pipes is to reduce the speed at which valves close and pumps operate. By slowing down these actions, you can minimize the sudden changes in fluid velocity that trigger water hammer. This can be achieved by adjusting the valve closure time or implementing a gradual start-up and shut-off procedure for pumps.

Increasing Pipe Diameter and Lowering Flowrate

Another effective method to mitigate water hammer risks is to increase the diameter of the pipes and lower the flowrate. By increasing the pipe diameter, you can reduce the pumping velocity and alleviate the pressure fluctuations that cause water hammer. Lowering the flowrate also helps to minimize the rapid changes in fluid velocity, preventing water hammer from occurring.

Using Surge Tanks or Surge Alleviators

Surge tanks or surge alleviators can be employed as a solution to fix vibrating water pipes. These devices allow fluid to enter or leave the pipe during water hammer events, absorbing the excess energy and preventing it from causing vibrations. Surge tanks act as a buffer, reducing the impact of water hammer and protecting the integrity of the piping system.

It is important to choose the most suitable solution based on the specific characteristics of your piping system. By implementing these solutions, you can effectively fix vibrating water pipes and ensure the smooth operation of your plumbing system.

Importance of Proactive Management and Risk Assessment

Proactive management and risk assessment are crucial components in preventing water hammer and ensuring the long-term integrity of the piping system. By taking a proactive approach to managing water hammer risks, facilities can identify potential issues before they escalate into more significant problems. Risk assessment plays a key role in quantifying and mitigating vibration and fatigue risks associated with water hammer. This systematic approach allows facilities to evaluate the potential impact of water hammer and implement appropriate preventive measures.

Implementing proactive management strategies, such as conducting regular inspections and monitoring, can help detect early signs of water hammer and address them promptly. By identifying and resolving potential sources of water hammer, facilities can prevent incidents, improve safety, and optimize the performance of their piping systems.

Benefits of Proactive Management and Risk Assessment:

- Early detection and prevention of water hammer incidents

- Improved safety for personnel and equipment

- Long-term integrity and reliability of the piping system

- Optimized performance and reduced maintenance costs

“Proactive management and risk assessment are essential in preventing water hammer incidents and ensuring the long-term integrity of the piping system.” – Plumbing Expert

By integrating proactive management practices and risk assessment into design, operational, and maintenance practices, facilities can effectively prevent water hammer and its associated risks. This proactive approach not only enhances the safety and reliability of the piping system but also reduces the potential for costly repairs and downtime. With proper proactive management and risk assessment, facilities can stay ahead of water hammer issues and maintain a smooth and efficient plumbing system.

Importance of Proper Pipe Design and Support

Proper pipe design and support are crucial factors in preventing water hammer and maintaining the integrity of the piping system. The design phase should consider key elements such as pipe diameter, flowrate, and fluid characteristics to ensure optimal performance and minimize the risk of vibrations. By selecting the appropriate pipe size and using flow control devices, the velocity of the fluid can be regulated, reducing the likelihood of water hammer incidents.

Pipe supports play a vital role in preventing vibrations and maintaining the stability of the piping system. They should be designed to withstand the forces generated by water hammer and keep the pipes in their static, at-rest position. Adequate bracing and reinforcement can minimize pipe movements and help prevent damage. By prioritizing proper pipe design and support, facilities can significantly reduce the risk of water hammer and prolong the lifespan of the system.

Importance of Pipe Design

Proper pipe design is essential for preventing water hammer and its damaging effects. When designing the piping system, several factors should be considered, including pipe material, size, layout, and the velocity of the fluid. By selecting the appropriate pipe diameter and material, the flow characteristics can be optimized, reducing the likelihood of water hammer incidents. Additionally, careful planning and layout of the pipes can minimize the potential for sudden changes in flowrate, thus mitigating the risk of water hammer.

Importance of Pipe Support

Effective pipe support is critical for preventing vibrations and maintaining the stability of the piping system. Properly designed supports can absorb the forces generated by water hammer, keeping the pipes in their intended position and minimizing the risk of damage. Adequate bracing and reinforcement should be provided to prevent excessive movement and maintain the system’s integrity. Regular inspection and maintenance of pipe supports are also necessary to ensure their continued effectiveness in preventing water hammer.

| Benefits of Proper Pipe Design and Support | Key Considerations |

|---|---|

| Prevents water hammer incidents | Selecting appropriate pipe diameter |

| Minimizes the risk of pipe vibrations | Optimizing flow control devices |

| Improves the overall integrity of the system | Proper pipe layout and planning |

| Extends the lifespan of the piping system | Adequate bracing and reinforcement |

Proper pipe design and support are crucial factors in preventing water hammer and maintaining the integrity of the piping system. The design phase should consider key elements such as pipe diameter, flowrate, and fluid characteristics to ensure optimal performance and minimize the risk of vibrations. By selecting the appropriate pipe size and using flow control devices, the velocity of the fluid can be regulated, reducing the likelihood of water hammer incidents.

Importance of Regular Maintenance and Inspection

Maintenance and inspection are key factors in preventing pipe vibrations and addressing water hammer issues. Regular upkeep ensures the proper functioning of valves, pumps, and other equipment, reducing the sources of water hammer. Visual inspections play an important role in identifying potential signs of water hammer, such as pipe movements or visible damage. Additionally, periodic testing using vibration analysis tools provides valuable data on the condition of the piping system and helps detect any anomalies. By implementing a comprehensive maintenance and inspection plan, facilities can prevent pipe vibrations and prolong the lifespan of the system.

Benefits of Regular Maintenance and Inspection:

- Prevents pipe vibrations and potential damage

- Identifies and addresses water hammer issues promptly

- Ensures the proper functioning of valves, pumps, and equipment

- Detects and resolves anomalies through vibration analysis

- Prolongs the lifespan of the piping system

To illustrate the importance of regular maintenance and inspection, let’s take a look at a table showcasing the potential risks and consequences of neglecting these practices:

| Risks | Consequences |

|---|---|

| Undetected water hammer | Burst pipes and structural damage |

| Malfunctioning valves and pumps | Disruption of fluid flow and inefficiency |

| Unaddressed pipe movements | Stress on pipe supports and potential failure |

| Failure to detect anomalies | Costly repairs and downtime |

By regularly maintaining and inspecting the piping system, these risks and consequences can be mitigated, ensuring a safer and more reliable plumbing infrastructure. Implementing a proactive maintenance and inspection approach is essential for preventing pipe vibrations, maintaining water hammer, and optimizing the overall performance of the system.

Conclusion

In conclusion, fixing water hammer and vibrating water pipes requires a systematic approach and the implementation of proven methods. By understanding the causes and effects of water hammer, facilities can effectively address this plumbing problem and prevent further damage.

A comprehensive risk assessment is crucial to identify potential water hammer situations and mitigate the associated risks. This includes analyzing the piping system, identifying high-risk locations, and implementing appropriate solutions tailored to the specific characteristics of the system.

Proactive management, proper pipe design and support, regular maintenance, and inspection are key factors in preventing water hammer and maintaining the integrity of the piping system. By prioritizing these practices, facilities can ensure a quieter and more reliable plumbing system.

In summary, fixing water hammer involves a combination of understanding, assessment, and proactive measures. By following the practical tips outlined in this article, facilities can successfully address water hammer issues, prevent pipe vibrations, and optimize the performance of their plumbing systems.

FAQ

What is water hammer?

Water hammer, also known as hydrostatic shock, is a phenomenon that causes vibrations in water pipes. It occurs when there is a rapid change in fluid velocity, resulting in a shock wave that travels through the pipe and causes movement and noise.

What are the causes of water hammer?

Water hammer can be caused by various factors, such as valves shutting off quickly or pumps starting or stopping suddenly. The primary sources of water hammer include acoustic/pulsation, momentum, and machinery.

What are the risks associated with piping vibration?

Piping vibration can lead to failures that pose risks to facilities, equipment, and personnel. These failures can result in explosions, environmental damage, and facility shutdowns.

How can potential water hammer situations be identified?

Identifying potential water hammer situations can be challenging but essential for preventing damage. Computer programs can model pipe systems and reveal potential problems, allowing for accurate identification and resolution of water hammer issues.

What are the effects of water hammer?

Water hammer can cause burst pipes, damaged supports, leakage at joints, and even structure collapse. The shock wave caused by water hammer changes fluid velocity and creates high-pressure zones, leading to potential failure.

How can water hammer be diagnosed in plumbing systems?

Water hammer can be diagnosed by observing pipe movements, listening for banging noises, and monitoring flowrate changes. Common signs include banging water pipes and clanging, rattling, or rumbling noises when plumbing fixtures or valves shut off.

What are the solutions to fix vibrating water pipes caused by water hammer?

Effective solutions include slowing down valve closures or pump operations, increasing pipe diameter, lowering flowrate, and using surge tanks or surge alleviators. The best solution depends on the specific characteristics of the piping system.

Why is proactive management and risk assessment important for preventing water hammer?

Proactive management and risk assessment help identify, quantify, inspect, measure, and mitigate vibration and fatigue risks associated with water hammer. By incorporating prevention strategies into design and operational practices, facilities can prevent incidents, improve safety, and optimize performance.

How does proper pipe design and support prevent water hammer?

Proper pipe design considers factors such as pipe diameter, flowrate, and fluid characteristics. Pipe supports are designed to withstand the forces generated by water hammer and keep the pipe in its static, at-rest position, minimizing pipe movements and reducing the risk of damage.

Why is regular maintenance and inspection important for preventing pipe vibrations?

Regular maintenance and inspection help identify potential signs of water hammer, such as pipe movements or visible damage. It also ensures the proper functioning of valves, pumps, and other equipment, reducing the sources of water hammer and prolonging the lifespan of the system.